During the last year process conditions have been optimized by Titania with flat test tubes, but at the pre-industrial bath scale. Both the results of this last phase and the conclusions of SEALANT will be presented at a final meeting of the project, which will take place on June 26 at the CIDETEC technology center. One of the objectives achieved through this research has been to demonstrate the feasibility of replacing surface polluting treatments with new technologies that are able to provide a high performance in terms of resistance to corrosion.

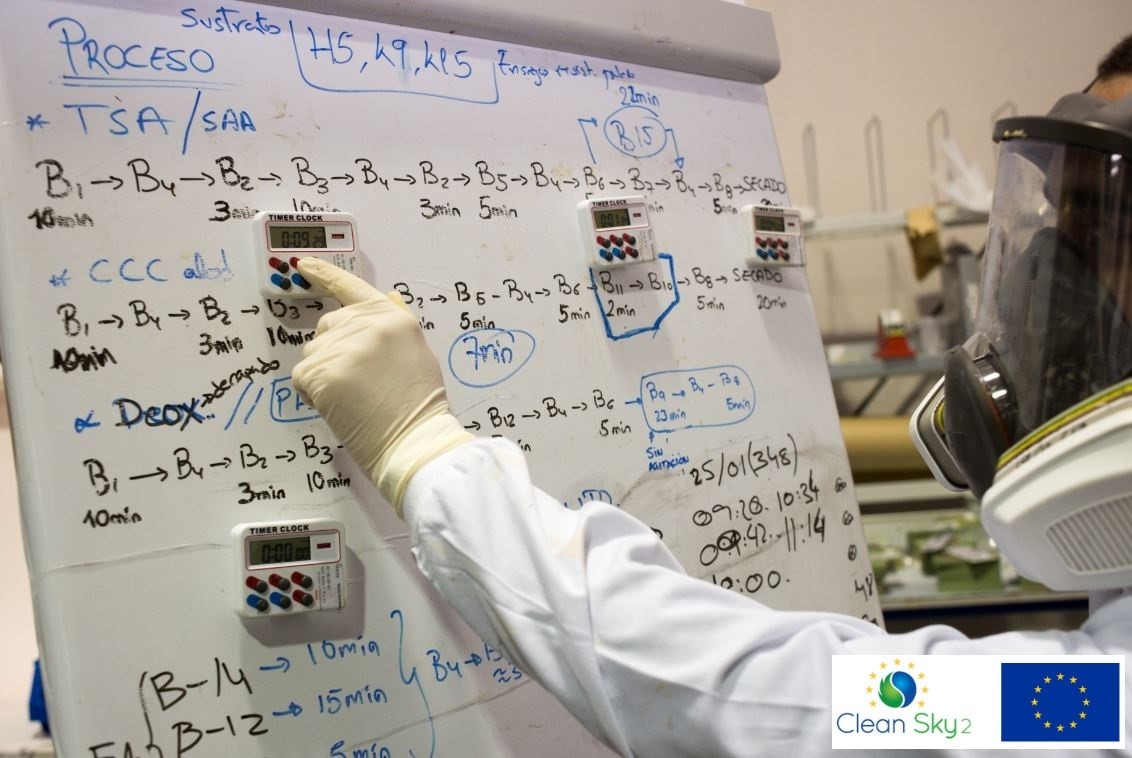

In addition to its role as project coordinator, Titania has also assumed technological responsibilities such as the fine-tuning process, optimizing the pilot-scale formulation, implanting the optimized conditions on other aluminum alloys of interest and the execution of standardized characterization for process validation.

“This project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 717173”.