At Titania we have implemented different special aeronautical processes that allow us to offer a panel manufacturing service for testing and research, adapted to the particular needs of each requesting company. These panels can be used in quality control work and in the development of R&D projects.

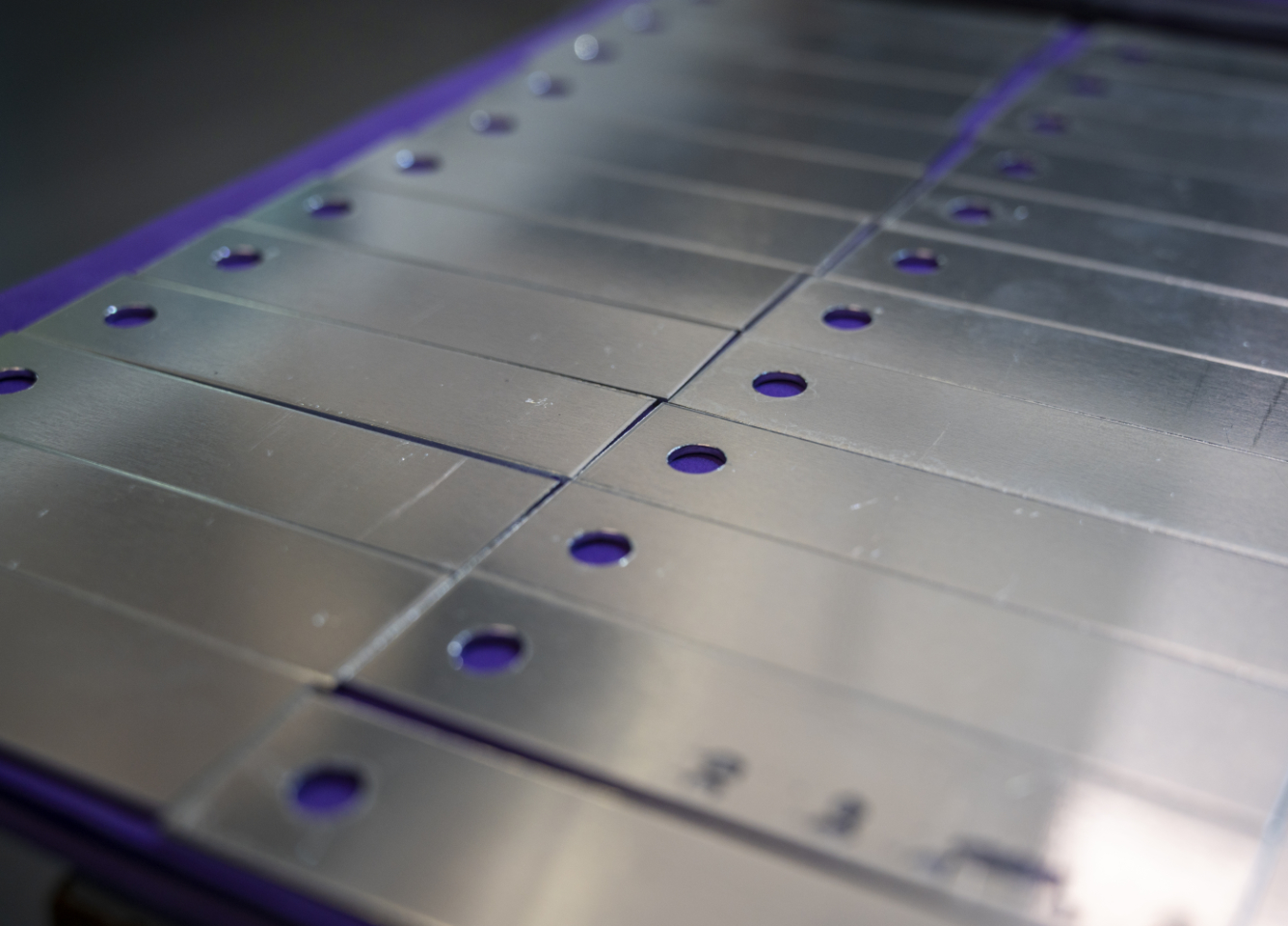

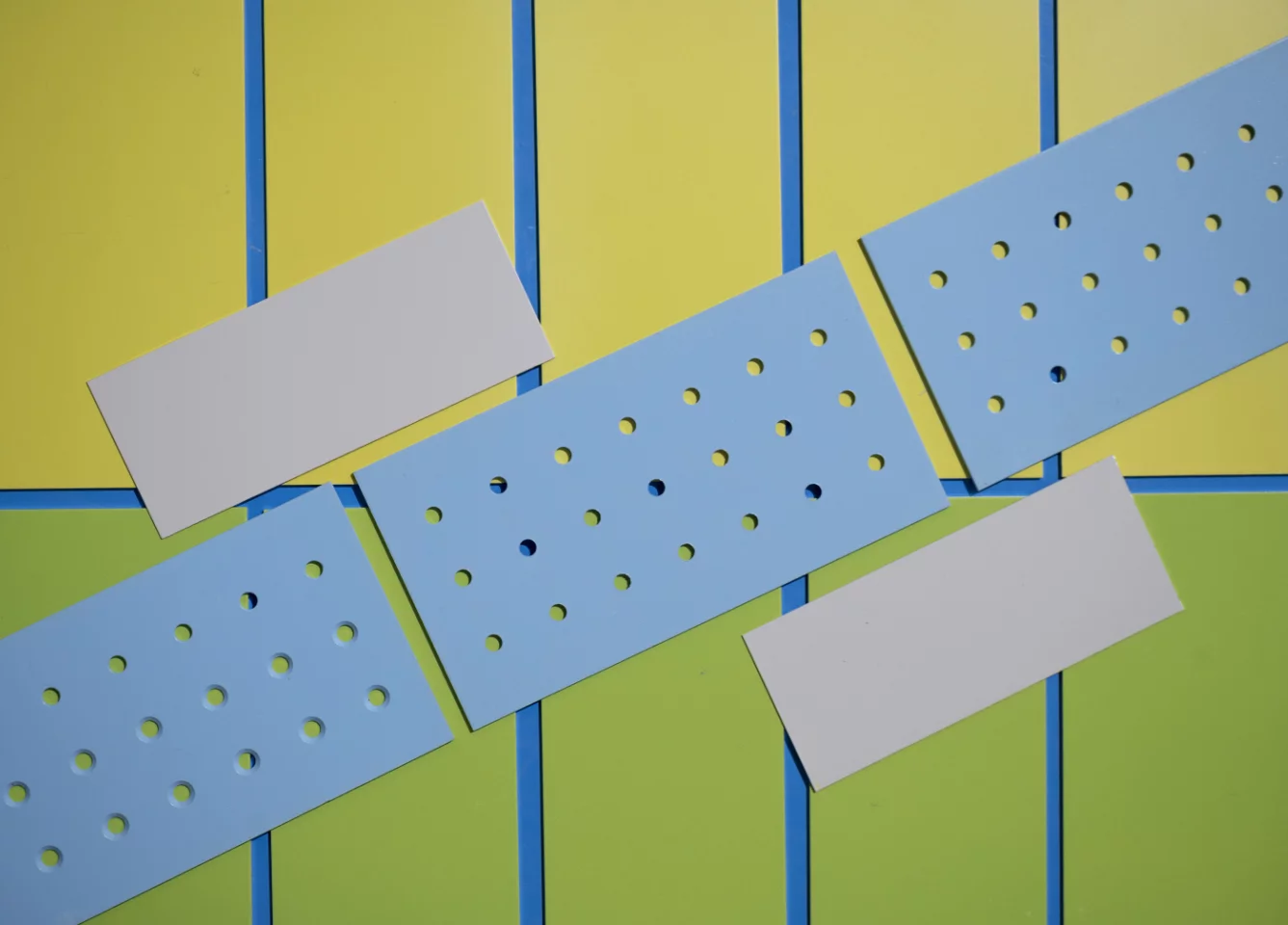

To this end, our facilities have a bath line, with manufacturing processes approved by Airbus, in which we carry out different surface treatments on aluminium alloys. In addition, this line is complemented by a spray booth which also complies with the requirements of the aeronautical sector regulations. The combined use of both facilities allows the production of bare or coated metal panels with different types of surface finishes on demand.

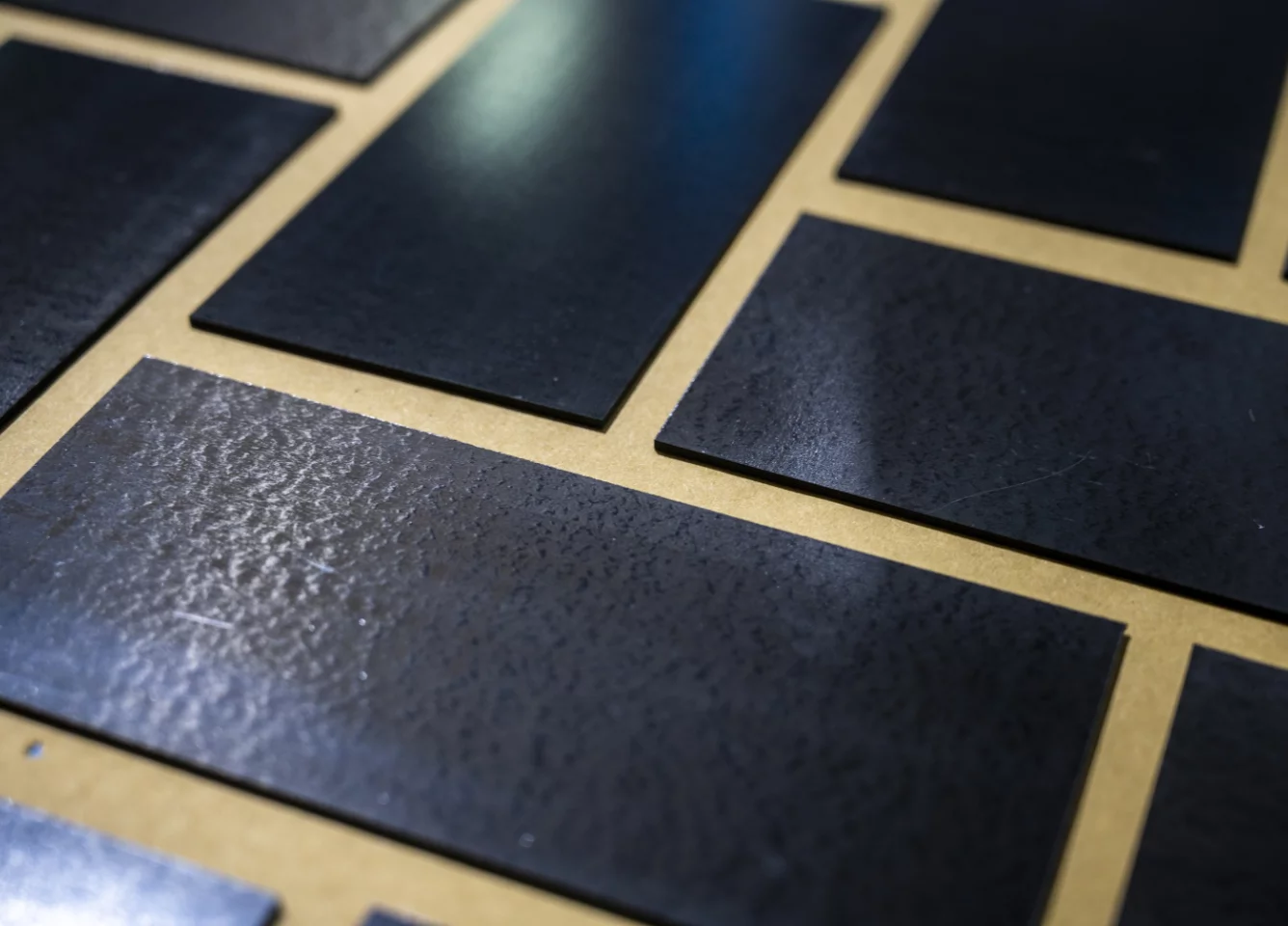

In addition, we have a second processing centre which allows us to carry out the complete manufacture of panels using composite materials. These facilities consist of a 25 m3 freezer, a clean room and an autoclave that allow us to manufacture this type of panel to aeronautical standards. With these capabilities we manufacture panels with varied characteristics, ranging from monolithic carbon fibre panels to sandwich panels and assemblies glued or joined using different types of fasteners.

Type of panels

Contact with our expert

José Rodríguez