In December 2022, Titania received the final award of the Innovative Aerostructures for Emission Reduction (AIRE) project. This research project focuses on the search for more sustainable aircraft manufacturing methods by reducing pollutant emissions in the production process and in the aircraft during service.

The development of this R&D+i project is divided into several lines of research:

Thermoplastics (TP): Investigating the manufacturing processes of high-performance thermoplastics with superior mechanical properties for the construction of primary and secondary structures.

Liquid resin infusion: Process optimisation through the study of new manufacturing processes for composite materials.

Intelligent assembly: Optimising machining, supplementing and positioning processes through research into intelligent assembly processes.

Testing technologies: Research in material characterisation technologies for simulation, non-intrusive testing and inspection and design for functional testing and wiring diagnostics.

<p align=”justify”>To meet this challenge, a multidisciplinary consortium has been created, comprising six companies with the necessary skills and knowledge to cover the project’s entire value chain. Specifically, the consortium is made up of:</p>

ACITURRI, project leader in charge of developing manufacturing technologies for thermoplastic materials, together with the development of tooling for sandwich composite material.

AERYS, project partner in charge of developing demonstrators for electrical test equipment.

AIRBUS, project partner in charge of providing both its engineering skills and the appropriate requirements to validate the results obtained by the rest of the partners.

MTORRES, project partner in charge of researching new technologies to improve the assembly process of high-level aeronautical surfaces.

PRINCIPIA, project partner in charge of researching simulation methodologies for impact and damage detection in composite panels.

TITANIA, project partner in charge of the development and performance of new characterisation tests on metallic materials and composites.

Several technology centres will also be collaborating with the consortium, in particular: CIDAUT, TECNALIA, FIDAMC, UCA, CATEC, UPM, UJA, UC3M, URJC and US.

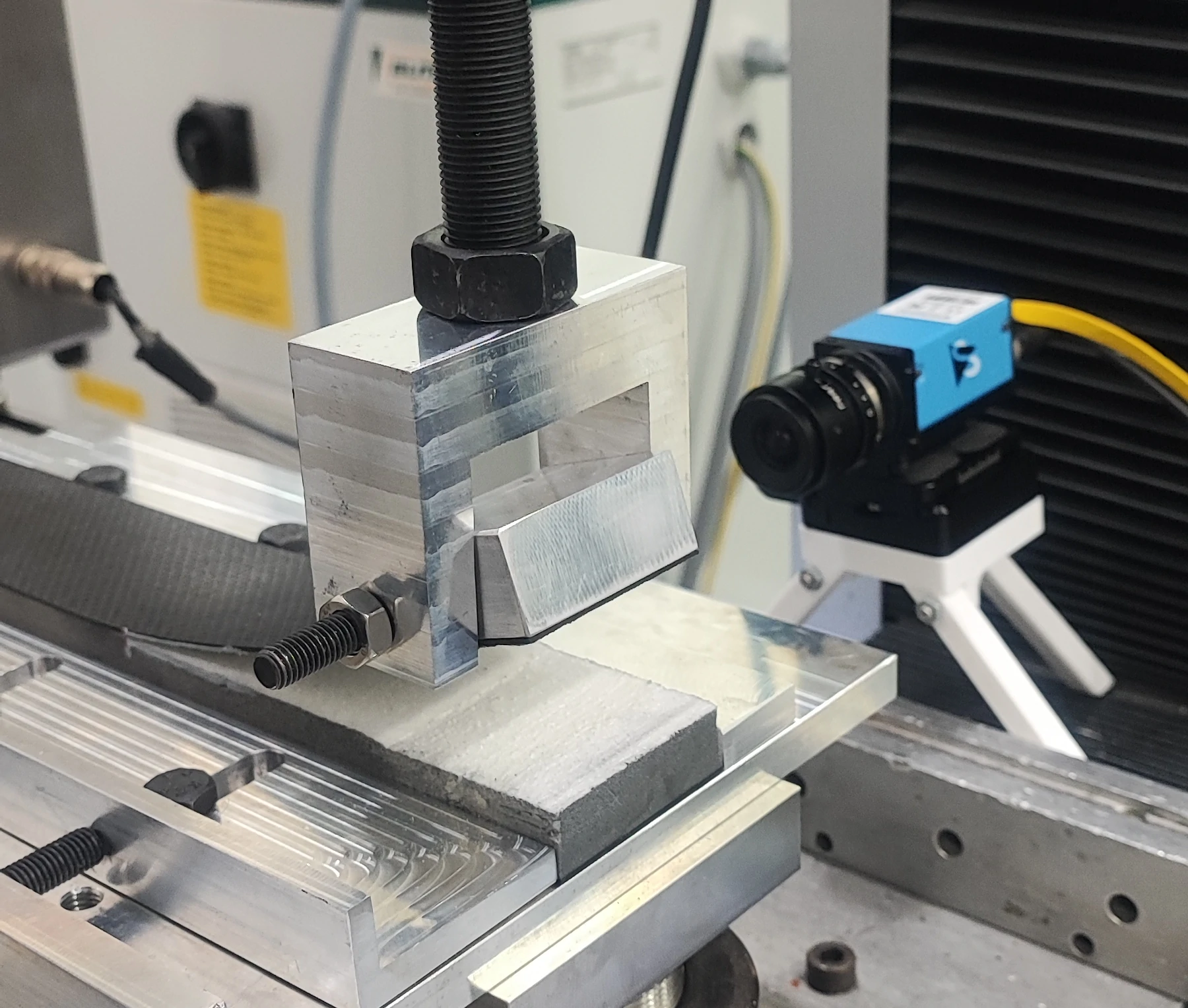

In this project, Titania will focus its efforts on the development, manufacture and fine-tuning of new tests adapted to the requirements of the materials and technologies being researched. In addition, special tests are envisaged to achieve unique characterisations of both metallic and composite materials together with hybrid and multifunctional substrates which they would form part of in certain types of simulation. The development of this project will allow Titania to expand its capabilities so it can carry out dynamic tests with high strain rates, as well as developing new static tests on composite materials.

The AIRE project is subsidised by the CDTI (PTAG-20221019), with the support of the Ministry of Science and Innovation, and by Next Generation EU funds, specifically through the European Union’s Recovery and Resilience Mechanism, established by Council Regulation (EU) 2020/2094 of 14 December 2020, establishing a European Union Recovery Facility to support recovery from the COVID-19 crisis, and regulated under Regulation (EU) 2021/241 of the European Parliament and of the Council of 12 February 2021 establishing the Recovery and Resilience Mechanism.