The DIMPESA project was created with the aim of advancing towards a level of knowledge and technology that will enable the development of more sustainable, competitive and functional aerostructures. To this end, it will focus on research into materials and manufacturing processes, as well as on the evolution of both areas towards more automated, efficient and controlled methods. This will be achieved by evaluating the materials, manufacturing processes and assembly of aeronautical components.

The project arises from a key need of industry in general and, in particular, of the aeronautics industry: to advance in the decarbonisation of the sector. It addresses three strategic lines of work that will contribute to the overall reduction of the industry’s consumption levels, both in the production stage and in the subsequent aircraft operation phase:

Technologies with lower energy consumption during manufacturing (out-of-autoclave processes).

Integration of structures.

- Integrated structures.

- New assembly techniques.

To meet this challenge, a multidisciplinary and balanced R&D&I consortium has been created in which the industrial driving company is supported by the experience and know-how of two SMEs with extensive experience in this type of research. The consortium is made up of:

- AIRBUS DEFENCE AND SPACE (AIRBUS). A division of Airbus Group dedicated to the military aviation, defence, security and space business.

- TNP. A technology company focused on creating products based on the ArcelorMittal R&D innovation stack.

- TITANIA. A technology company specialising in materials testing and the development of project-based research in the field of materials science.

In addition to the core member companies, it should be noted that the consortium will enjoy the collaboration of three universities and five technology centres, all with leading departments in the research areas in which they participate, who will make their knowledge, infrastructures and material resources available to the members of the consortium in order to facilitate the achievement of the project’s objectives.

Titania’s challenge in this project focuses on:

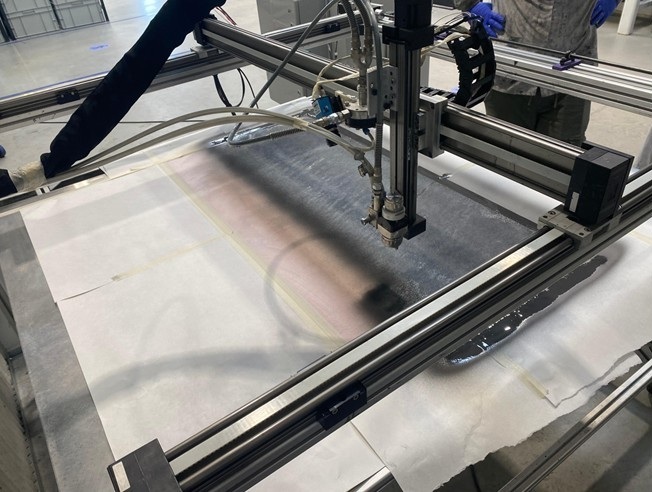

Developing its manufacturing of composite materials in order to support the design of multifunctional and environmentally friendly composite materials, using out-of-autoclave methods, including Liquid Resin Infusion (LRI).

Developing automated homogeneous resin doping and deposition methods on support materials.

DIMPESA starts in July 2024 and will last 18 months. It is subsidised by the Centre for Technological Development and Innovation (CDTI) through the 2024 call of the Science and Innovation Missions Programme of the State Plan for Scientific Research and Innovation 2024-2027, within the framework of the Plan for Recovery, Transformation and Resilience.