After months of work, the RESINSURF project continues to advance thanks to the consortium’s efforts. On this occasion, we’re focusing on sharing the progress of the pilot 2 tests, which is where Titania is concentrating its efforts.

This phase consists of the validation at pilot plant level of the hexavalent chromium (Cr VI) substitution process in the protection of light alloys, together with the implementation and validation of different process control and monitoring systems.

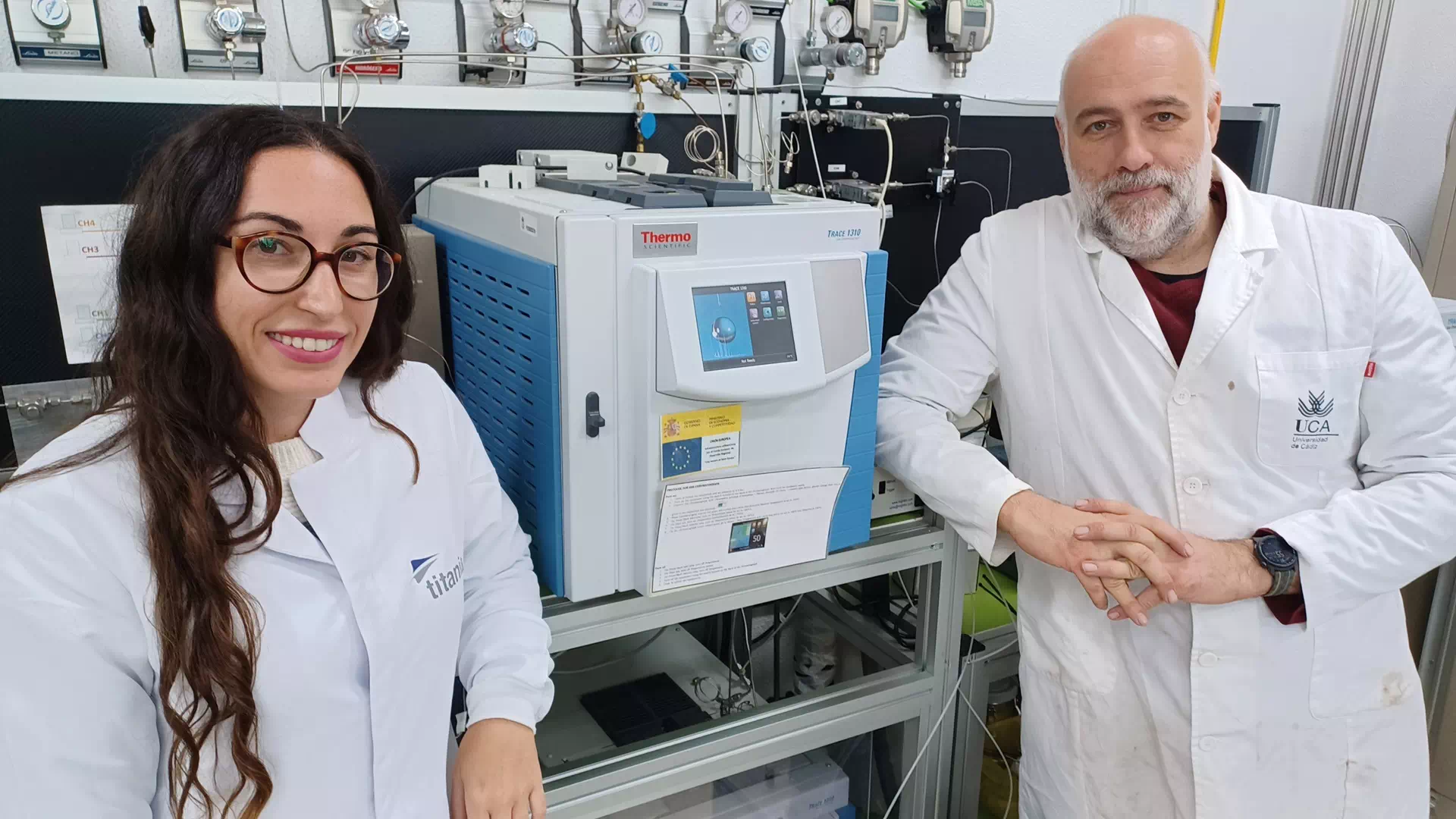

In particular, during this stage, the aim is to verify the transferability of the technological solutions adopted in other applications, including anodising, conversion coating and electrophoretic deposition of paint on light alloys. Titania was initially going to acquire a chromatograph to analyse and quantify the evolution of the volatile compounds in the paint to be used for the anaphoretic coatings. However, in the end it was decided not to purchase the equipment and instead to collaborate with the University of Cadiz, which has expert resources in the field. In other words, the University of Cadiz has a research group specialised in “Structure and Chemistry of Nanomaterials” with knowledge and experience in the application of techniques for which the chromatograph is used. This decision strengthens ties and promotes the transfer of knowledge between the university and the company.

At the same time, also at this stage of the project, Titania is in the process of acquiring consumables such as:

Raw materials, in particular the aluminium sheets and frames to be used in the chemical processes.

Chemical Products for baths, and lacquer for the anaphoretic process.

Throughout this phase, Titania is maintaining direct communication with the manufacturer of the lacquer used. In addition to Titania, CIDETEC and the University of Cadiz are participating in these ongoing conversations with the aim of defining:

Product components for subsequent chromatograph analysis and test methodology.

The cleaning process of the tanks and the ultrafiltration system of the anaphoretic process and filling strategy.

All in all, RESINSURF is progressing according to plan and its objective of investigating processes for the substitution of hexavalent chromium coatings.

The RESINSURF project started in January 2024, will last 36 months and is part of the Interreg Sudoe programme co-financed by the European Commission through European Regional Development Funds (ERDF).