The MALTA 2020 project (Manufacturing and Automation of Low-Cost Thermosets for Competitive Advantage) has come to an end and has successfully achieved the objectives set. This research, promoted by a consortium led by Airbus D&S and in which Titania has participated together with the companies Aerotecnic and Nanotures, started in 2018 with financial support from Corporación Tecnológica de Andalucía (CTA), an entity that supports Andalusian companies and universities by promoting regional R&D+i and technology transfer.

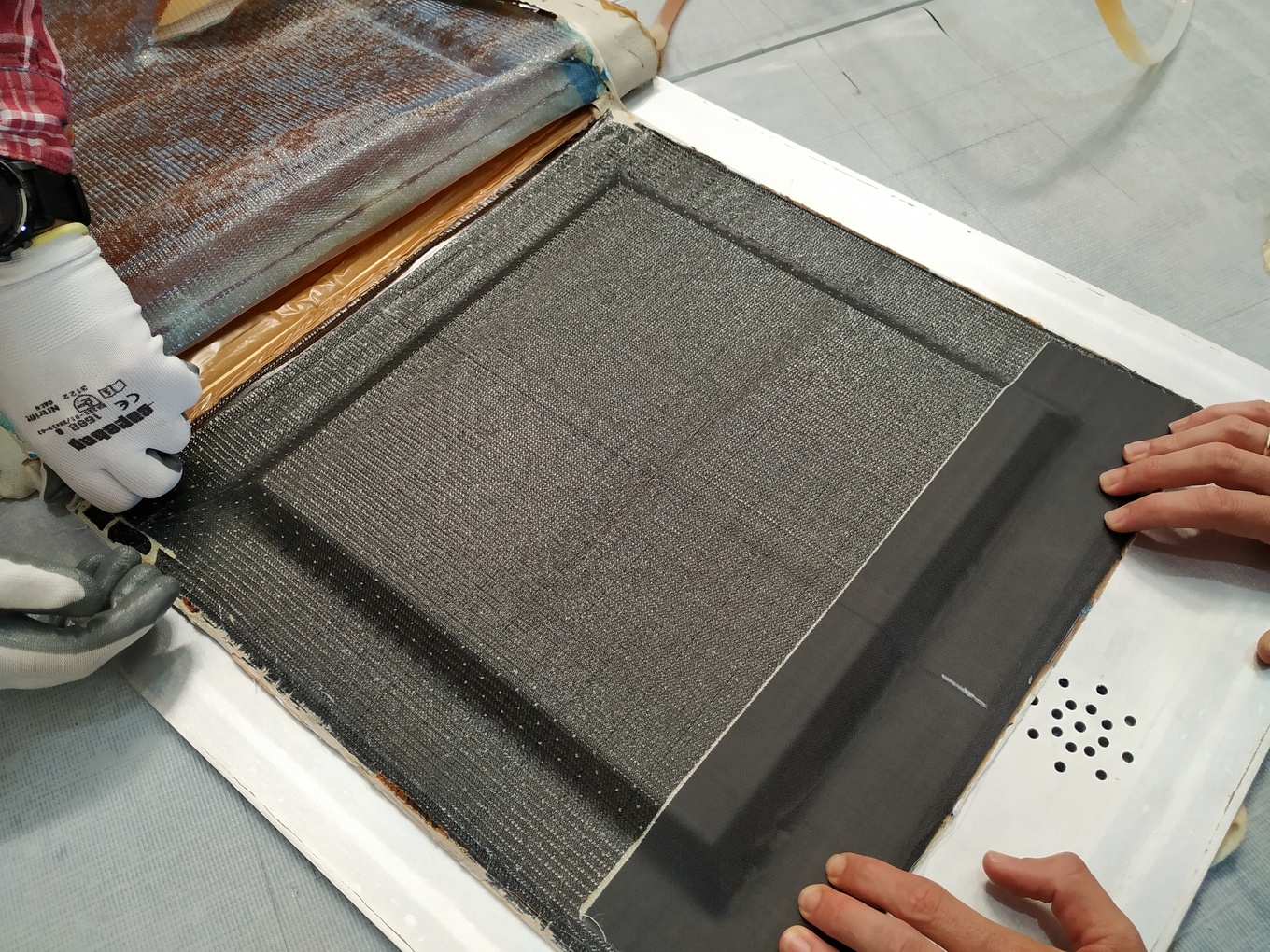

As far as Titania is concerned, the project has allowed the implementation of a new manufacturing process for composite materials based on liquid resin infusion, and which complements the already existing autoclave manufacturing system, widely used in the aerospace sector. Additionally, an extensive characterisation of the new postulated resins has been carried out both in monolithic and sandwich structures, which has served to develop new tests, some of them catalogued by Airbus as highly complex, as well as to execute tests in conditions never before evaluated in Titania.

In general, the MALTA 2020 project has been a success for Titania, a company that provides its clients with a service covering both tests and special processes, resulting in new orders for the manufacture of monolithic panels through the process of resin infusion together with the corresponding test plans.

The project enjoyed an incentive granted by CTA, fully subsidized by the Ministry of Economy, Innovation, Science and Employment of the Junta de Andalucía and by the Ministry of Economy and Competitiveness.

If you want to know more about this project, we recommend reading this post published on our website:https://bit.ly/3lLpjVv