Reducing the processes in autoclave will make a 180º turn in these types of processes. These processes deal with the increasing automation, reducing the intermediate steps and the costs associated. This Project attempts to increase the usage of composite materials (carbon fiber or glass fiber) in aeronautical, rail or automotive structures (in this case, especially in electric vehicles).

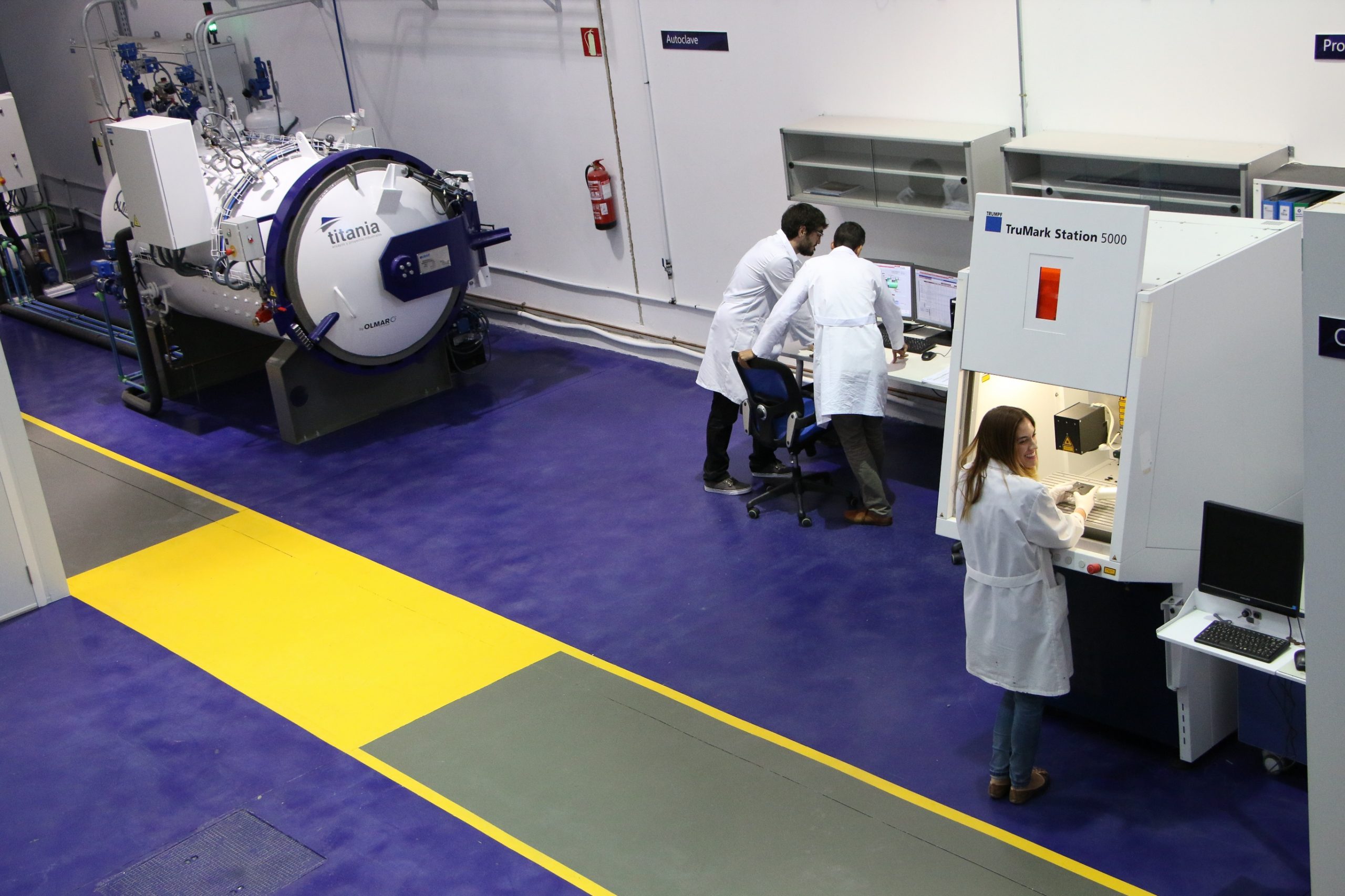

Titania will be in charge of the integration of the autoclave in its R&D centre in composites manufacturing, and the production of the elements manufactured by protrusion in the demonstrator with prepreg material, and the characterization of the process and of the materials used. CT Ingenieros will provide its knowledge in aeronautical structural design, definition and control of manufacturing processes and design during the pultrusion process. Eurecat (member of TECNIO) provides leading technology and research in composite materials. The project will be carried out in Andalucia.

The general secretary of the Centre for the Development of Industrial Technology (CDTI) has valued the scientific and technological quality of the Pultrubeam project and has provided financial support to the 2016 program for the Innterconecta European Union program ERDF (European Regional Development Fund)