On 3 July, Leticia Cabrera Correa defended her Doctoral Thesis at the School of Engineering of the University of Cadiz. With this act, Titania’s first industrial PhD put an end to the research work she has been carrying out over the last four years. During this time, Leticia has been studying the microstructure, mechanical properties and corrosion behaviour of the Scalmalloy® alloy under certification conditions. The work was carried out jointly by the Corrosion and Protection Laboratory of the University of Cadiz and Titania. The thesis was supervised by Professor Javier Botana and Doctor Leandro González, and supervised at Titania by Pedro Astola, head of the R&D department.

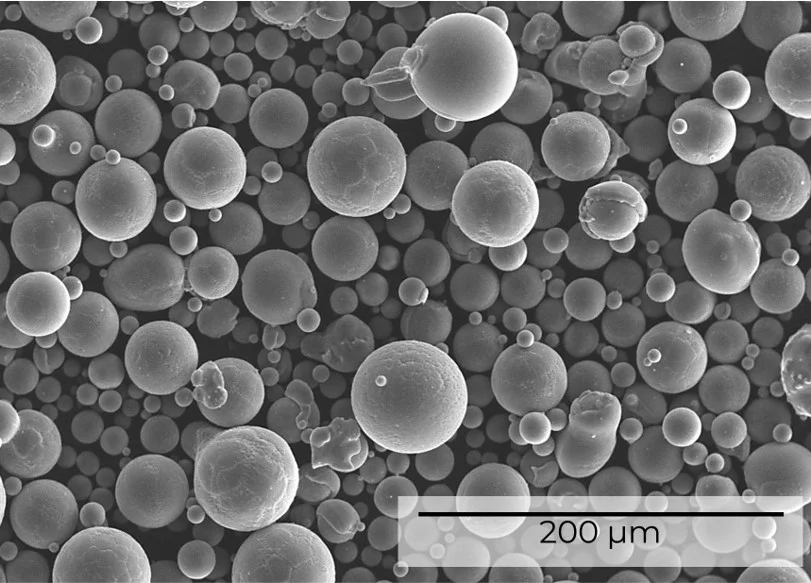

Scalmalloy® is an aluminium alloy developed by APWORKS, an Airbus spin-off, which has been specifically designed to be used in additive technology. Currently, there are only 16 research centres, universities or companies certified for the use of this material, with the University of Cadiz’s Corrosion and Protection Laboratory being one of them. The work developed in this doctoral thesis has allowed the publication of three high-impact scientific articles related to the characterisation of the Scalmalloy® alloy under certification conditions. The results obtained have identified a limitation of use in those applications where the material is exposed to temperatures close to 150°C.

The execution of this doctoral thesis has allowed Titania to incorporate its first doctoral student with an industrial mention. This type of thesis encourages the development of scientific research in collaboration between universities and companies. Thus, the doctoral candidate is able to develop their skills in two very different fields, the academic and the industrial.

In its commitment to research and knowledge transfer with other research centres and universities, Titania is currently involved in two industrial theses in conjunction with different research groups at the University of Cadiz. One of these theses is studying the optimisation of catalysts for hydrogen generation and the other, the simulation of the stainless-steel rolling process by means of finite elements. After the completion of these projects, Titania will have a total of five PhDs on its staff (three women and two men), of which three will have an industrial mention.

Here is the link to the publications:

- Effect of the heat treatment on the mechanical properties and microstructure of Scalmalloy® manufactured by Selective Laser Melting (SLM) under certified conditions

https://doi.org/10.1016/j.matchar.2022.112549

- Pitting and intergranular corrosion of Scalmalloy® aluminium alloy additively manufactured by Selective Laser Melting (SLM)

https://doi.org/10.1016/j.corsci.2022.110273

- Localized and stress corrosion cracking of sensitized Al-Mg-Sc-Zr alloy manufactured by laser powder bed fusion