The tests aimed at the certification of the technology have been supported by previous studies with advanced characterization techniques of material surface, such as optical microscopy, contact angle, roughness, scanning electron microscopy (SEM), surface energy and surface chemical composition (XPS).

Thanks to this project Titania got a deeper knowledge on this technique, including issues such as the cleaning capacity of surface contaminants, the lifetime of the treatment and the limiting conditions of the process, as well as its application in damaged material removal prior to repairs.

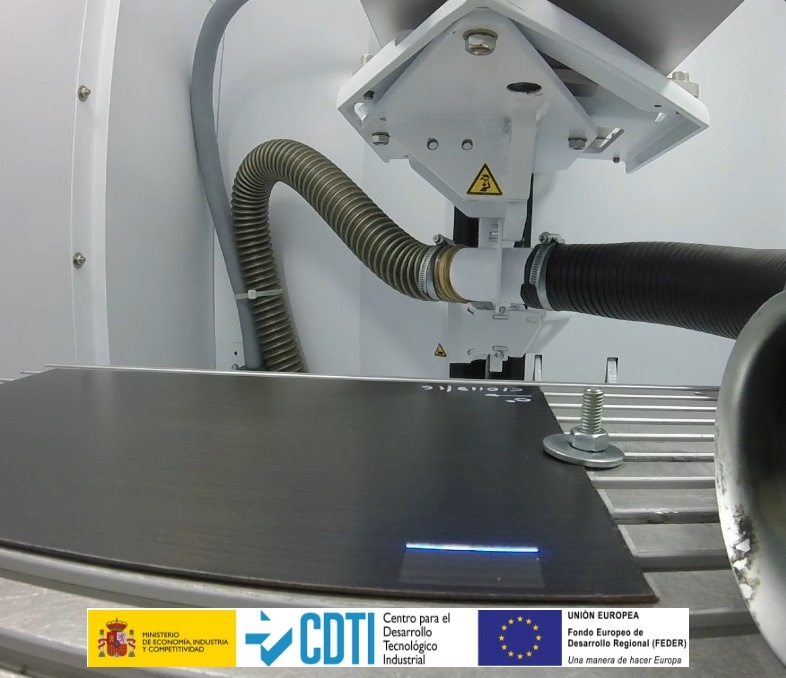

In the Air-Union final phase, the industrial simulation of the process for large aeronautical structures was executed, allowing the project to reach a TRL5 of technology maturity.