Our testing laboratories are accredited by ENAC / ILAC according to ISO/IEC 17025. Our quality system is also certified according to ISO 9100 and EN 9100. In addition, the standardised tests performed in our laboratories are NADCAP (PRI) accredited in the following areas: MTL, NMMT and NDT.

We are approved by the world’s leading aircraft manufacturers. As a result, our tests are included in the following lists: Airbus Qualified Test Method List (QTML), Bombardier Supplier List (BAERD-GEN-018), Boeing Approved Sources D1-4426 y Embraer Supplier Qualification.

This set of approvals allows us to evaluate the properties of materials used in various industrial sectors: transport, metallurgy, infrastructure and energy.

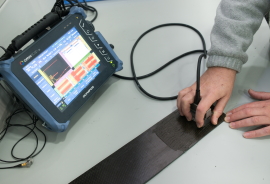

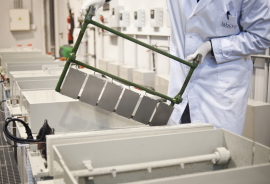

We have more than 300 standardised tests in place. These tests can be used for the certification of metallic materials, such as steels, aluminium alloys, titanium, copper and nickel; for the control of metal fabrication processes, composite materials, adhesives, sealants, paints and cutting fluids; for the control of material treatment processes such as welding, heat treatment or anodising; and for the technical reception of raw materials.

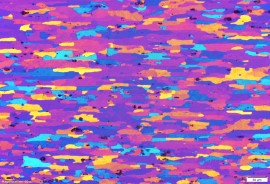

In our laboratories, materials can be characterised in terms of their mechanical, microstructural, physical, chemical composition and corrosion properties. For this purpose, we perform tensile tests, hardness tests, salt spray chamber tests, metallographic tests, adhesion tests and paint layer thickness tests, among others.

To find out if we have implemented the test you are interested in, select the family of tests for the desired material

Composites

Metals

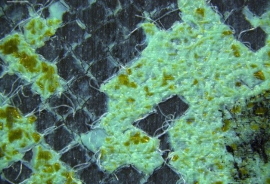

Sealants and adhesives

Surface treatments and paintings

Contact with our expert

Paloma Rodríguez